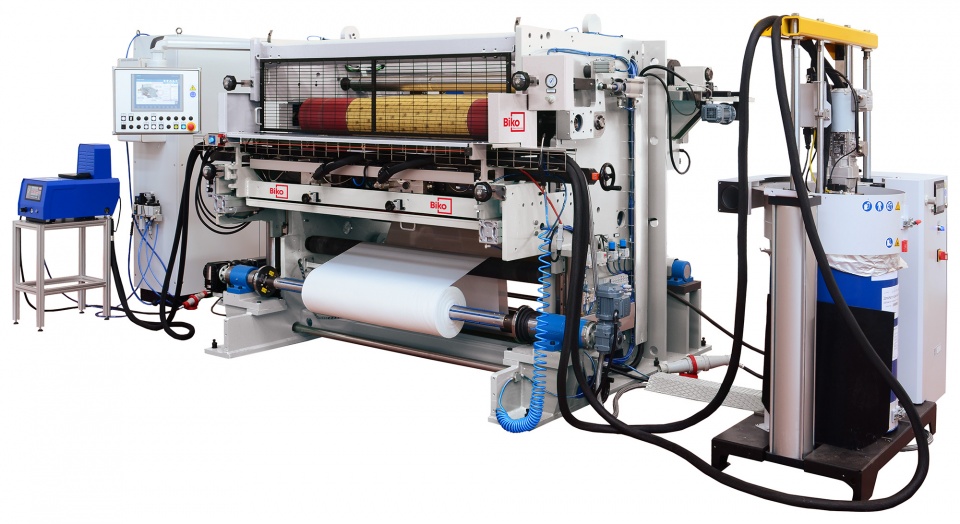

Laminating Machine Type LM-HM-S

Hot-Melt Based Laminating Machine

The LM-HM-S laminating machine is designed to laminate various type of materials together through the application of hot melt adhesive. LM-HM-S is a high-performance machine, suitable for the continuous process of jumbo rolls.

Technical Data

- Useful unwinding width: 1,650 mm, up to 600 mm dia. roll

- Laminated material tension is controlled by dancer roll

- Both unwinders have automatic web edge control

- Unwinders are motorized

- Spread shaft before lamination

- Variable speed drive up to 50 m/min

- Hot Melt gluer application head, slot die type, covering the whole web width

- The Hot Melt system can guarantee a minimum of 18 gr/m2 of applied glue

- Application head with variable application width, to a min. of 900 mm

- Hot Melt application head can be displaced both horizontally and vertically with fine adjustment

- Drum melter for 200 liter resin drum

- Both laminating rolls (top and bottom) are rubber coated, 250 mm dia.

- Useful rewound jumbo width: 1,750 mm, up to 600 mm dia.

- The complete machine is electronically controlled to automatically manage torque control on each station. Feedback to the operator is given by display featuring also touch screen for parameters control

Options

- Unwind and Winder max roll diameter increase, up to 900 mm

- Second drum melter, tubes and valves

- Cleaning product melter

Size and Power

- Overall machine dimensions: 6 x 3 x 2.5 m

- Approx. weight: 9,000 kg

- Installed power: 30 kW

- Air consumption: 2500 Nl/h