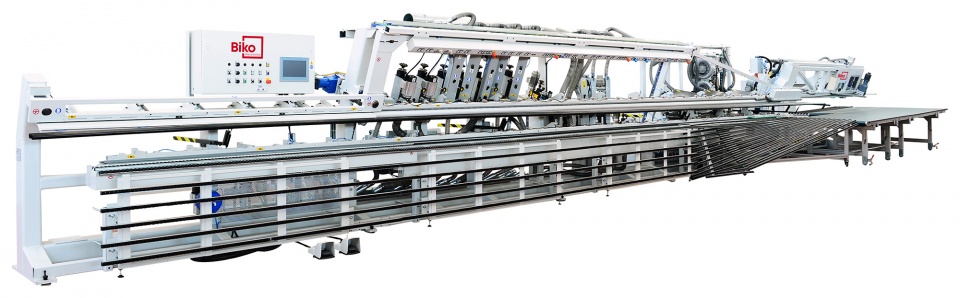

Double Continuous Skiving Machine Type CSM05

Continuous Skiver for Any Joint Type with Gluer, Dryers, Tape Applicator, Semi-Auto Joint and Press

The skiving machine type CSM05 is manufactured to process simultaneously both laps of paper and cloth wide belts with maximum joint length of 2000 mm (special execution for segmented belts up to 3400 mm). The CSM05 is indicated for converters with high productions.

Technical Data

- Automatic continuous cycle with a feeding conveyor belts system, at variable speed

- Ideal either for overlapped joints or butt joints

- Cycle with variable speed up to 12 m/min. (367 FPM)

- Standard working direction from left to right

- In the standard version, the machine can be provided with a maximum of 15 working units and 2 gluers (roller NGA-15 or spray NSA), 8 working units on the upper working line and 7 on the lower one

- Infrared oven, 3000 mm length, with stepless regulation, installed after the gluing unit

- Inserting station for 2000 mm wide belts. 3400 mm is also possible, for segmented belts processing

- Motorized carpet to guide the belt out of the skiving machine

ATA—Automatic Tape Applicator

The tape is introduced once through the gluing and drying devices. The tape is driven automatically and applied to the belt lap. The tape ends are the same length of the joint.

- Gluing unit and drying element for the tape

- PLC control

- Photocell counter for detecting of the joint length

- Shear cutter for automatic tape cutting

- Standard cutting angle 45°, 55°, 67°, 75° (other angles upon request)

- Tape roll unwinder: standard width 19 mm (25 mm also possible)

- Tape roll max. diameter 300 mm, internal diameter 75 mm

SAJ-A—Semi-Automatic Joining Station

The CSM05 skiving machine can be equipped with semi-automatic joining station and continuous press BPN-W.

- After being processed through units, gluer, oven and tape (optionally) one lap of the belt is continuously driven by the machine conveyor belt

- The second lap is released by the machine where the operator can easily collect it

- The operator has only to insert the free lap into a guiding belt, helped by a reference support bar

- The joining station syncronizes the two laps by matching the edges, performing an automatic belt joining

- The closed belt is then processed by the continuous press BPN-W

- The press beam is heated

- With the addition of this device, productivity of 4 belts/minute for 1300 x 2620 mm belts can be reached

Size and Power (with Joining Station)

- Overall machine dimensions: 18.9 x 4.4 x 2.5 m

- Approx. weight: 9,600 kg

- Installed power: 58 kW

- Air consumption: 17,000 Nl/h (air blows included), 7,000 Nl/h (without air blows)