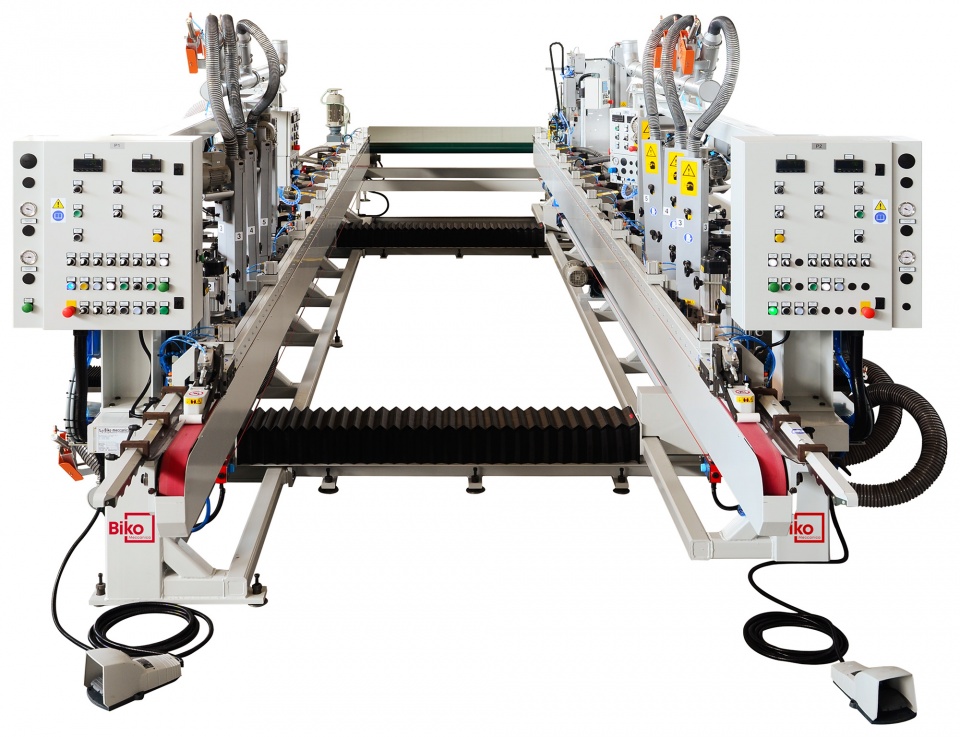

Double Continuous Skiving Machine Type TWIN

Continuous Skiver for Segmented Belts—Any Joint Type with Gluer, Dryers and Tape Applicator

The skiving machine type TWIN is manufactured to process simultaneously both laps of paper and cloth wide belts. There is practically no limit to the joint length, therefore the twin line is the best solution for segmented belts processing. The TWIN machine is indicated for converters with high productions.

Technical Data

- Two parallel working lines: one is fixed and the other one can be moved according the length of the belt

- Automatic continuous cycle with a feeding conveyor belts system, at variable speed

- Ideal either for overlapped joints or butt joints

- Cycle with variable speed up to 12 m/min. (367 FPM)

- Standard working direction from left to right

- In the standard version, the machine can be provided with a maximum of 12 working units and 4 gluers (roller NGA-15 or spray NSA), 6 working units plus 2 gluers on the left working line and 6 working units plus 2 gluers on the right one

- Infrared oven, 3000 mm length, with stepless regulation, installed after the gluing unit

- Inserting station for 3400 mm segmented belts

- Roller table in the inserting area, to help operator during material feeding

- Roller table as support in between the two skiving lines, on hinges to be swinged up or down

ATA—Automatic Tape Applicator

The tape is introduced once through the gluing and drying devices. The tape is driven automatically and applied to the belt lap. The tape ends are the same length of the joint.

- Gluing unit and drying element for the tape

- PLC control

- Photocell counter for detecting of the joint length

- Shear cutter for automatic tape cutting

- Standard cutting angle 45°, 55°, 67°, 75° (other angles upon request)

- Tape roll unwinder: standard width 19 mm (25 mm also possible)

- Tape roll max. diameter 300 mm, internal diameter 75 mm

Options

- Working groups designed to receive the automatic tracking system, ideal for production of segmented belts

Size and Power

- Overall machine dimensions: 15.5 x 3.5 x 2.2 m

- Approx. weight: 8,000 kg

- Installed power: 36 kW

- Air consumption: 17,000 Nl/h