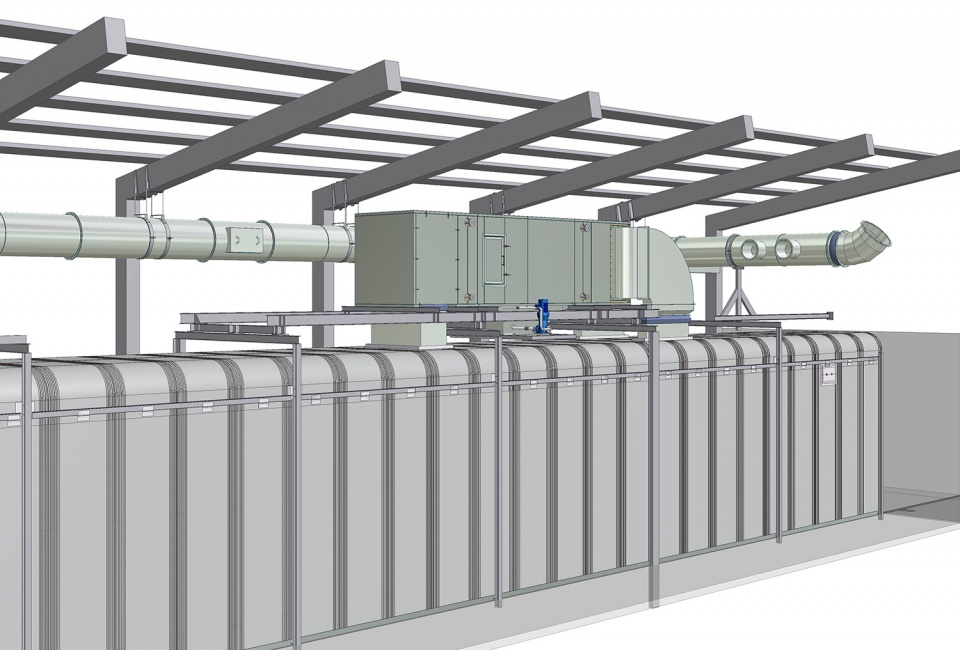

Festoon Dryer

Festoon Dryer for Coated Abrasive Production

The Festoon Dryer is designed to be installed in line with coating and strewing machines for coated abrasive production. The dryer, being part of the maker, is mostly designed according to customer requests. Its size can change based on production parameters and of course site of construction. Based on these specifications the oven can reach hundreds of meters of length. Biko realizes all the parts related to heat management as: heat distribution and exchanging, exhaust system, isolation and humidity control.

Technical Data

- Oven length and temperature based on curing time and processed web parameters

- Compatible with 1650 mm web maximum width

- Heating machines with different possibility of heat exchanging: steam, thermal oil, gas heater

- Heating machines able to generate air volume of 30,000 m3/hour

- Air ducts with adjustable air grids for an even air distribution

- High quality isolation system for zero waste of heat

- Possibility of moisture machine integration