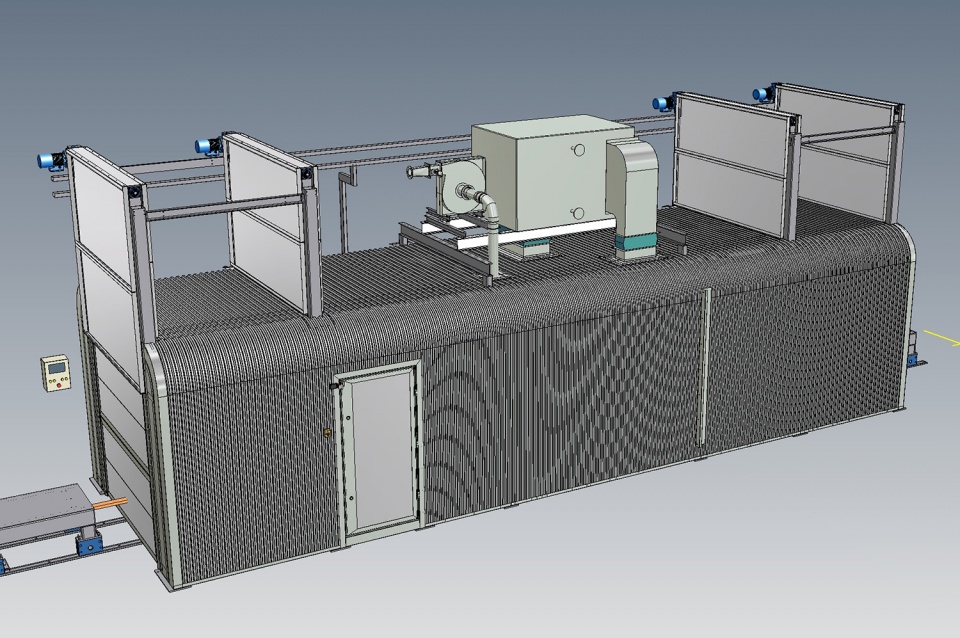

Jumbo Curing Oven Type COT

Trolley Based Jumbo Curing Oven

The Jumbo Curing Oven Type COT is designed to perform post-treatment on processed jumbos. The oven is usually installed nearby the maker area to permit a quick passage from the coating plant winder to the oven inlet. Oven sizes are designed and realized based on customer requests. Based on these specifications, the jumbo curing oven size could vary from a few meters long up to practically any length. Biko realizes all the mechanical parts involved in the jumbo transportation and manipulation and installs the whole oven: transportation, heat distribution and exchanging, isolation, electrical components and software.

Technical Data

- Oven speed, length and temperature based on curing time and processed web parameters

- Compatible with 1650 mm and 2050 mm wide jumbos

- Processing jumbos up to 1600 mm diameter (4 tons)

- Step oven solutions with trolley-based transportation system (jumbo on pallet)

- Step oven solution is suggested when supply of jumbo rolls to the post-treatment system is not continuous

- Heating machines with several possibilities of heat exchanging: steam, thermal oil, gas heater

- Heating machines able to generate air volume of 20,000 m3/hour

- Air ducts with adjustable air grids for an even air distribution

- Automatic manipulators working in high temperature area

- Automatic manipulators to manage jumbo loading and unloading

- Automatic manipulators to manage oven curves (based on factory layout)

- High quality isolation system for zero waste of heat

- Possibility of jumbo cooling zone integration

- Main electronic controller for oven managing with touchscreen interface for operator

- Tracking system to log each processed jumbo data