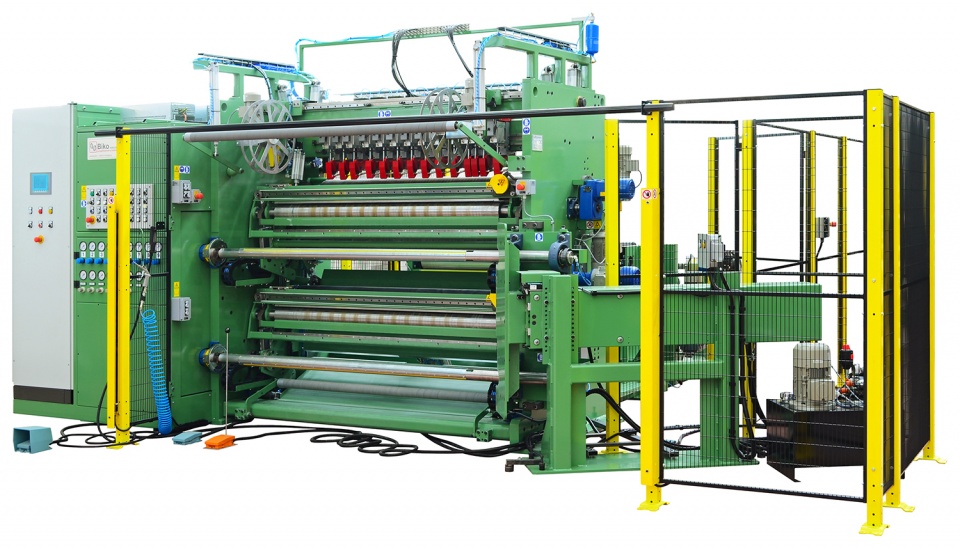

Jumbo Roll Slitter Type TR-N2

Heavy Duty, Very Narrow Cut Slitter

The roll slitter machine type TR-N2 is designed to cut rolls of abrasive paper and cloth and to rewind them with grain both inside and outside. TR-N2 is a high-performance machine which is suitable for the continuous process of heavy jumbos. It can moreover cut from full jumbo width rolls of 20-25 mm width for the production of flap discs, flap wheels and economy rolls.

Technical Data

- Variable speed up to 60 m/min

- Cut by pneumatic knifeholders or with fixed knife set

- Expanding shafts on both unwinder and rewinder sides

- Automaitc web alignment on rewinder

- Pneumatic unwinding brake, adjustable

- Unwinder maximum diameter 1000 mm

- Rewinders maximum diameters 600 mm (700 mm on single shaft)

- Easy to operate rewinders thanks to flag opening shafts

- Automatic length measuring device with preset automatic slow-down

Knifeholders

- Pnumatic knifeholders with pneumatic clamping, positioning by hand wheel (KH-50)

- Pneumatic fixed knife set (FKS) for cutting width less than 50 mm out of the whole slitting width

- Quick selection of the two cutting systems

Options

- Speed up to 100 m/min

- Separate unwinder up to 1250 mm diameter jumbo roll

- Automatic brake tension control

- Cross cutter

- Lift table to perform better insertion of the roll ends into the rewinding shaft

- Special display showing the distance between the individual knifeholders

- Support rolls on rewinding system for lock rolls-end

- Trim rewinders

Size and Power (TR-N2-1650 model with perimetric protections)

- Overall machine dimensions: 4.5 x 4.7 x 2.5 m

- Approx. weight: 5,500 kg

- Installed power: 31 kW

- Air consumption: 510 Nl/cycle