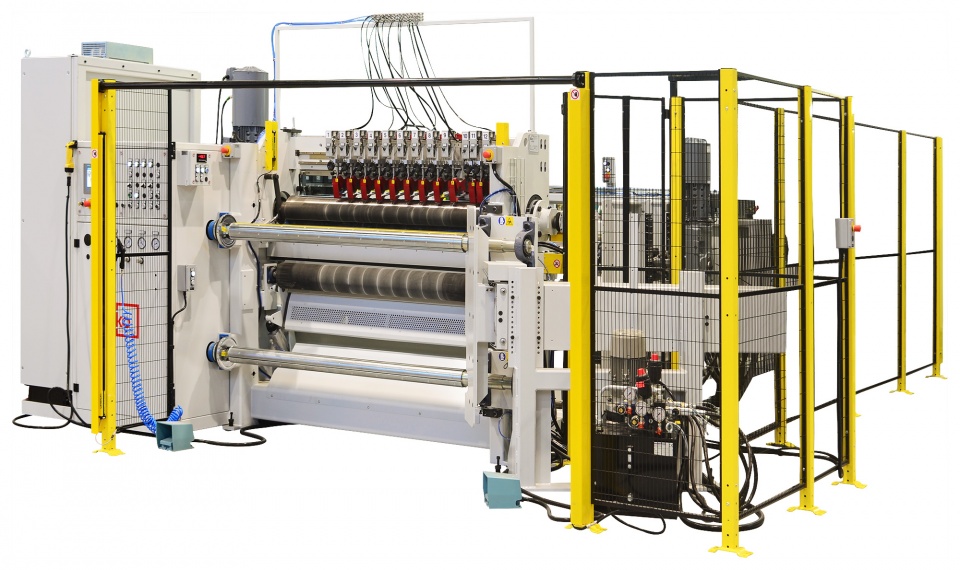

Jumbo Roll Slitter Type TRK

Heavy Duty Slitter

The roll slitter machine type TRK is designed to cut rolls of abrasive paper and cloth and to rewind them with grain both inside and outside. This is a high-performance machine which is suitable for the continuous process of heavy jumbos.

Technical Data

- Variable speed up to 60 m/min

- Expanding shafts on both unwinder and rewinder sides

- Automaitc web alignment on unwinder

- Unwinder maximum diameter 1000 mm

- Rewinders maximum diameters 500 mm (700 mm on single shaft)

- Easy to operate rewinders thanks to flag opening shafts

- Automatic length measuring device with preset automatic slow-down

- Automatic web tension control with direct rewinding shaft driving system and roll diameter control (on both unwinder and rewinders)

- Close loop motor control and touch screen featuring a special designed software to perform torque and brake control automatically

Knifeholders

- Pneumatic knifeholders with pneumatic clamping, positioning by hand wheel (KH-50)

- Pneumatic fixed knife set (FKS) for cutting width less than 50 mm on 310 mm working width

Options

- Speed up to 100 m/min

- Separate unwinder up to 1250 mm diameter jumbo roll

- Automatic brake tension control

- Cross cutter

- Lift table to perform better insertion of the roll ends into the rewinding shaft

- Special display showing the distance between the individual knifeholders

Size and Power (TRK-1650 model, with perimetric protections)

- Overall machine dimensions: 4.5 x 4.6 x 2.4 m

- Approx. weight: 3,300 kg

- Installed power: 15 kW

- Air consumption: 110 Nl/cycle