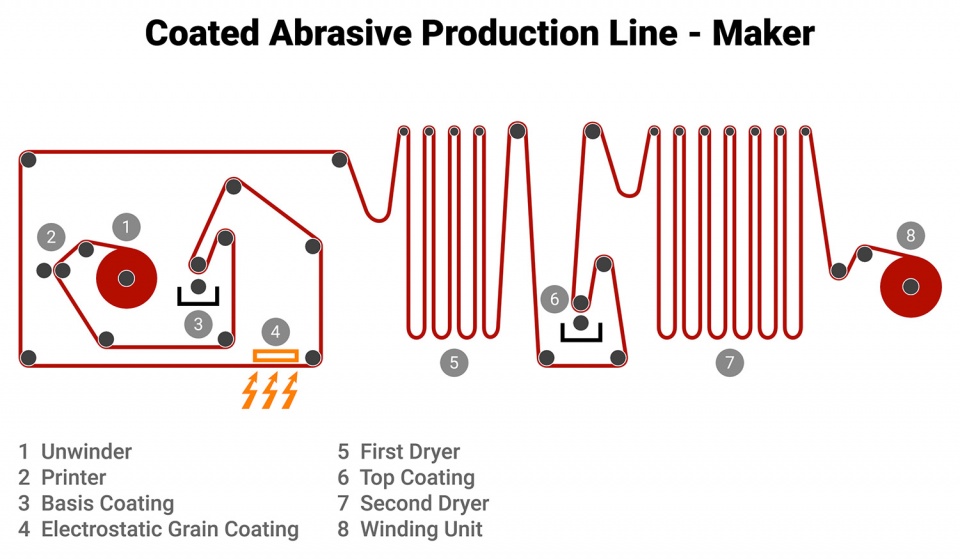

Coated Abrasive Production Systems

Full Maker Plant, Configurable in Width and Plant Length

Coated abrasive production lines, also called Makers, are made to realize flexible coated abrasive starting from various types of raw materials.

Winder, Coaters, Grain Strewing and Dryers, linked by a common automation system to realize coated abrasive of various type of backings:

- Paper

- Cotton cloth

- Polyester cloth

- Vulcanized Fiber

- Polyester Film

System configuration and available options allow the use of different type of resins and handling of a big variety of grain types and sizes.

A Maker can have a very basic configuration and automation: Single Unwinder, Single Dryer as well as equipped with high automation to reduce stop time and have less waste production: Double Unwinder with Auto-Splice function, Double Printer, Hot Winder with Post Curing Continuous Oven.

We cooperate with leader companies on systems and devices integrated in the maker plant, as for example the AC and DC high voltage generators for the grain strewing system.

As well as complementary equipment needed in the coating plant, one example are the mixers for resin preparation.