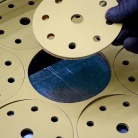

Die Cutting Machine Type EDP-W

Automatic Die Cutting Machine

The Die Cutting machine type EDP-W represents the highest automated system to cut coated abrasive discs starting from jumbo rolls. Feeding of material is automatic and managed by a transportation conveyor running together with a beam holder. Machine power permits to cut discs of various sizes and with a variable number of holes. Supported materials go from very thin and light paper to heavy coarse grit web. Depending on the disc size, number of holes and material type, more material layers can be cut at the same time.

Technical Data

- Useful material width up to 2050 mm

- Feeding system by pressing beam working against motorized conveyor

- Punching system mounted on traveling head covering the whole board width

- 25 tons of cutting force (45 and 60 tons available)

- Able to cut more web layers at the same time (up to 5 layers)

- 600 x 600 mm cutting tool mounting board

- Head displacement by servo motor for accurate cutting tool position

- Scrap material, from hole punches, is automatically collected and vacuumed from the cutting tool

- A dedicated software manages the whole process and a touch screen allows the operator to change all the settings

- The touch screen gives the possibility to optimize the position of the cutting footprints so as to minimize waste material as much as possible

Options

- Different cutting tonnage

- Cutting head rotating on its axis 180°

- Automatic Die Change

- Unwinders for Jumbo Rolls

- Automatic stacking system

- Automatic Pick & Place parts collection

- Waste Winder

Size and Power (EDP-W-1650 model, with 2 unwinders and stacking system)

- Overall machine dimensions: 7.0 x 7.1 x 3.0 m

- Approx. weight: 13,000 kg

- Installed power: 18 kW

- Air consumption: 200 Nl/h