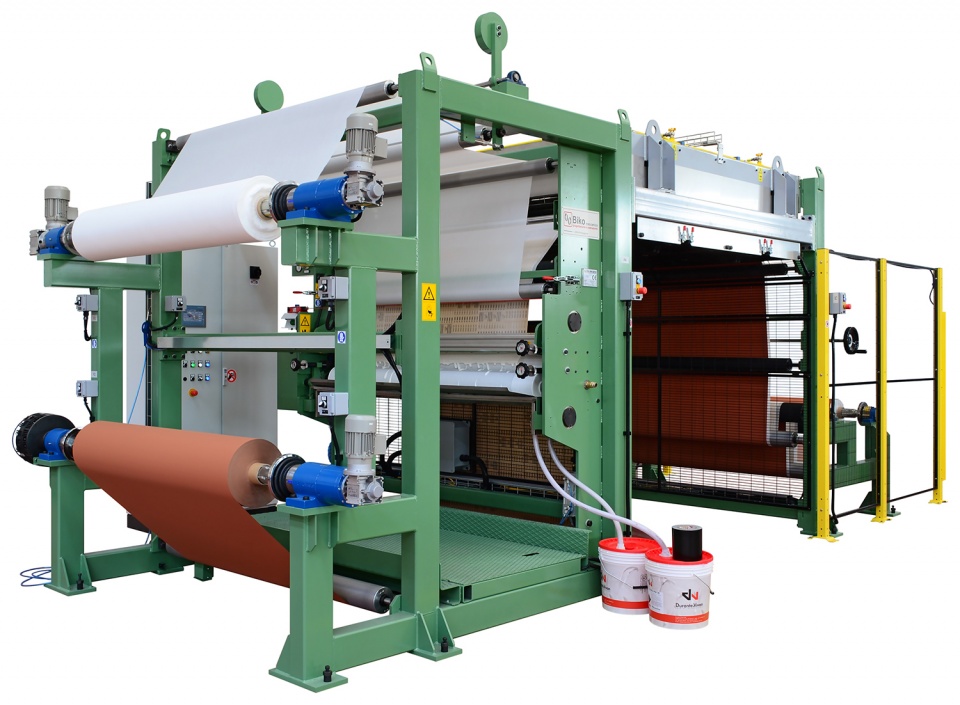

Laminating Machine Type LM-VG

Water Based Laminating Machine

The LM-VG jumbo roll laminating machine is designed to laminate Velcro or PSA on coated abrasive full width web backing side. LM-VG is a high-performance machine, suitable for the continuous process of jumbo rolls.

Technical Data

- Maximum web width: 1,650 mm

- Maximum diameter of the rolls: 1,000 mm (abrasive and velcro/PSA)

- Variable speed up to 15 m/min (depending on dryer length)

- Pneumatic brake on coated abrasive unwinder, manually adjustable

- Web edge guide on coated abrasive unwinder

- Low tension web control on velcro unwinder

- Two rubber covered shaft gluer, top shaft fixed, bottom shaft vertically sliding

- Bottom shaft pneumatically controlled with fine adjustment handles, one on each side

- Doctor blade for fine glue quantity adjustment

- Stainless steel glue basin, quickly removable

- Gluer is independently motorized

- Lamination system to link together velcro and coated abrasive backing

- Dryer for water evaporation, gas powered, featuring air flow control for a constant and even heat transfer

- Dryer length can vary based on requested machine performances

- Pull station to control web tension

- Rewinder up to 1,200 mm diameter jumbo, controlled by direct gearmotor

- The complete system is powered by AC motors, servo type where necessary

- Machine parameters are controlled by a dedicated software and available through a touch panel

Options

- Natural gas or LPG dryers

- Joining station on unwinder side

- Automatic unwinder brake pressure control

- Glue pump

- PSA unwinder and lamination

Size and Power

- Overall machine dimensions: 6.9 x 4.1 x 3.0 m

- Approx. weight: 4700 kg

- Installed power: 6.7 kW

- Air consumption: 500 Nl/h