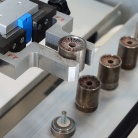

Mounted Flap Wheel Machine Type MFW-FORM

Automatic Flap Cutting and Wheel Forming

The flap wheel machine MFW-FORM automatically cuts the flaps, stacks them into a packet and forms the wheel into a ring. The ring is evacuated and is ready for final operations, i. e. injection and curing.

Technical Data

- Wheels diameter: from 20 to 80 mm

- Wheels width: from 10 to 50 mm

- Variable cutting speed

- Brushless motor for web feeding

- Touch screen panel for easy setup

- 2 or 3 unwinders for 500 mm max. diameter rolls

- Productivity on wheel diameter 30 mm, width 20 mm: up to 7 wheels per minute

Tools

- Each diameter size needs a tool kit. The kit can be easly changed

- Cutting and forming tools can be quickly changed by the operator

Options

- Automated and robotized unloading system for placing formed wheels on trays for subsequent resin injection

Size and Power

- Overall machine dimensions: 3.6 x 2.2 x 2.1 m (with 3 unwinders)

- Approx. weight: 1,300 kg

- Installed power: 2.5 kW

- Air consumption: 51 l/min