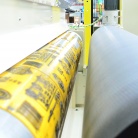

Printing Machine Type PM

Web Flexographic Printer

The PM jumbo roll printer is designed to print any logo on full width web backing side. PM is a high-performance machine, suitable for the continuous process of jumbo rolls.

Technical Data

- Useful width: 1650 mm or 2050 mm

- Unwinding station for rolls up to 1,200 mm dia.

- Unwinding pneumatic expanding aluminum shaft 3" dia.

- Automatic alignment of the unwinding material (automatic tracking)

- Pneumatic unwinding brake, automatically controlled

- Catwalk in between unwinder and printing station for operator access on printer setups

- Flexographic printer

- Variable speed drive up to 50 m/min

- A motorized brush works against web backing side, before the material enters the printing system

- One motorized rubber covered shaft as printer counter shaft, web runs over this shaft from the grain side

- One inflatable shaft for printer cliché support, idle

- One ink shaft, anilox type, ceramic coated. This shaft is motorized and by contact with the cliché transfers ink and motion

- One chamber doctor blade system transferring and dosing the ink to the anilox roll

- The chamber-doctor-blade-system works independently and is pneumatically controlled to maintain a constant link to the anilox roll

- The anilox roll, together with the doctor blade, is mounted on rails, pneumatically controlled and manually adjustable (both sides independent) for being pressed against the cliché

- The whole printing system (cliché shaft, anilox roll and doctor blade), is mounted on rails, pneumatically controlled and manually adjustable (both sides independent) for being pressed against the web and counter shaft

- The rewinder is independently motorized able to manage 1,200 mm dia. jumbo

- The rewinder is equipped with a 12 kW servo motor able to perform a maximum web tension of 3.5 N/mm decreasing to 1.5 N/mm at maximum jumbo diameter.

- The complete machine is electronically controlled to automatically manage torque control on each station. The installed software automatically calculates roll diameter on unwinder and rewinder. Feedback to the operator is given by display featuring also touch screen for parameters control.

Tools

- Variable speed up to 80 m/min

- Rewinder with roller bridge foe elongation web path

- Spreading roll system

- Joining table on unwinder side

Size and Power (with Joining Table and Perimetric Protections)

- Overall machine dimensions: 7.8 x 4.7 x 2.4 m

- Approx. weight: 4,700 kg

- Installed power: 12.9 kW

- Air consumption: 510 Nl/h